Absolute Encoders

Technical information

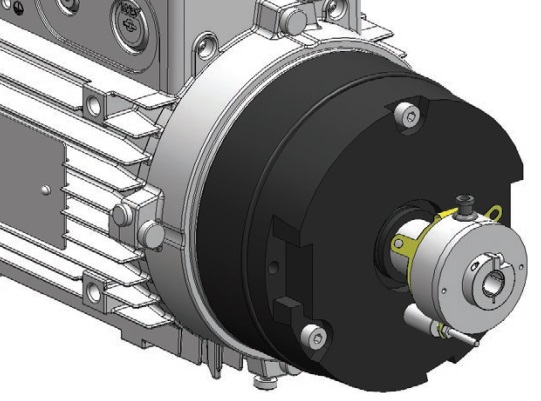

Feedback encoders are specifically designed for position feedback of electric motors. Thus they encompass standard interfaces suited to both communication and data exchange and mechanical installation in order to meet the requirements of a wide range of feedback applications. As they are installed in motor shaft they usually have small dimensions and in particular minimal depth; they are available in both solid and hollow shaft versions, anyway hollow shaft encoders are more compact, while solid shaft encoders are bigger and need flexible couplings, fixing clamps, adapting flanges or mounting bells for installation. Developed to meet critical requirements although IP protection rate is not necessarily high, they are able to handle high temperatures and speeds and boast excellent accuracy, safe signal transmission and high counting frequencies. Some of them feature insulated bearings protected against eddy currents and interface immunity.

Absolute Encoder Lika VietNam

Feedback encoders are offered in several versions providing:

• Incremental and absolute information

• absolute single-turn and multi-turn versions

• additional incremental / absolute tracks

• bearingless construction

• solid and hollow shaft mechanical interfaces

• highest resolutions

Application:

• general purpose electric motors (AC and DC)

• closed loop stepper motors

• brushless motors, servomotors, etc.

• rotary and linear generic applications